Toro 20370 walking mower

Serial: 312072687

Kohler PH-XT675-2011

Serial 4204102708

This was being operated when it ran over an article of clothing and came to an abrupt stop. It started and ran fine after, I'm told, but the owner subsequently found most of the oil puddled up on top of the deck the next morning.

I took a look and it is leaking oil from the front around where the sump cover and block mate up. There may also be a crack but this may just be a seam from the casting. I'm having a tough time telling so I took the engine off and am trying to remove the sump cover.

I removed the oil seal and all of the bolts and am able to get the cover to slide off about 1/2 inch down the shaft but then it hangs up abruptly. It moves enough to separate from the locating posts but won't move much further and I'm afraid to force it as I've only ever removed one of these in the past. I can see inside with a flashlight and it doesn't look like anything should be hanging it up. I can see the cam gear post (or what I believe to be cam related) is still in the cover but from my limited experience, that should slide right out. So it must be hanging up on the shaft?

Does anyone have any tips or words of encouragement?

Thanks you.

-

- Advertisement

Toro Oil Sump

17 posts

• Page 1 of 2 • 1, 2

Advertisement

Re: Toro Oil Sump

Probably got a bent crankshaft - common on rotary mowers like that - just a slight bend from perfectly straight, sump cover is gonna have a hell of a time coming off. Should have some oil tracer dye and a UV light , if it is cracked cover or crankcase, probably cost more to fix it than re-power with a new engine. bent crank can cause a crack in the sump too but that'd have leaked right down to the floor though. Did you actually clean up the oil mess first and run it a few minutes to observe where oil was coming from? If they had it tipped on the side to untangle the clothing from blade, oil likely would have leaked out the breather and into air cleaner housing, it'd take some time to seep down to fall on the deck.

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: Toro Oil Sump

Agree with BGS.

Hopefully you disabled the valve train. If you didn't the springs will be applying pressure to the camshaft. Other that all I can think of would be the PTO end of the crankshaft must clean and burr free in order for the closure plate to come off. Also verify the crankshaft didn't get bent during the event as that make hard to get the closure plate off.

BTW for oil leaks of unknown origin I prefer to use UV dye to verify where the leak is. The XT is however just glued together so it could just failed. I have seen where when an engine have had into by another tech to leak because didn't follow the RTV instructions.

When re RTVing it make sure every contact area is cleaned of and a surface prep/accelerator is used. You be surprise how much is left behind as with using Q-tips they get quite dirty during the use of the surface prep. Once assembly the screws are to be just finger tight for 12-24 then torqued spec. [I know it say 30 minutes but the RTV isn't fully cured during this time frame] This gives time for the RTV to stick and cure properly. Personally I am using Permatex 24163 with both my RTVs and thread lock compounds. A good example of not fully is the Ultra Black that can still squeeze out 12 hrs later when doing valve covers here.

Hopefully you disabled the valve train. If you didn't the springs will be applying pressure to the camshaft. Other that all I can think of would be the PTO end of the crankshaft must clean and burr free in order for the closure plate to come off. Also verify the crankshaft didn't get bent during the event as that make hard to get the closure plate off.

BTW for oil leaks of unknown origin I prefer to use UV dye to verify where the leak is. The XT is however just glued together so it could just failed. I have seen where when an engine have had into by another tech to leak because didn't follow the RTV instructions.

When re RTVing it make sure every contact area is cleaned of and a surface prep/accelerator is used. You be surprise how much is left behind as with using Q-tips they get quite dirty during the use of the surface prep. Once assembly the screws are to be just finger tight for 12-24 then torqued spec. [I know it say 30 minutes but the RTV isn't fully cured during this time frame] This gives time for the RTV to stick and cure properly. Personally I am using Permatex 24163 with both my RTVs and thread lock compounds. A good example of not fully is the Ultra Black that can still squeeze out 12 hrs later when doing valve covers here.

The truest measure of society is the how it treats its elderly, its pets, and its prisoners.

-

KE4AVB - Forum Pro

- Posts: 6174

- Joined: Mon Nov 04, 2013 11:23 am

- Location: TorLand

Re: Toro Oil Sump

Thank you for the guidance. I'll be back at it in the morning and will let you know what I find.

- lefty

- Forum Pro

- Posts: 1011

- Joined: Sun Jun 08, 2014 10:12 am

- Location: Massachusetts

Re: Toro Oil Sump

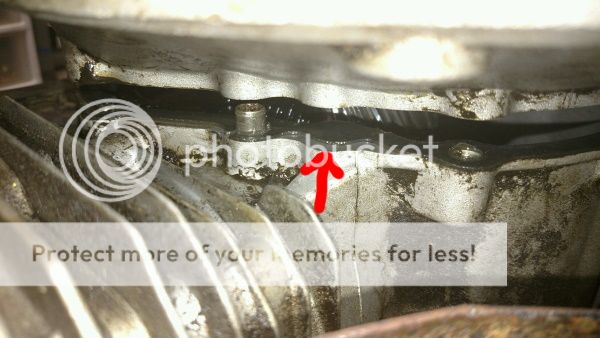

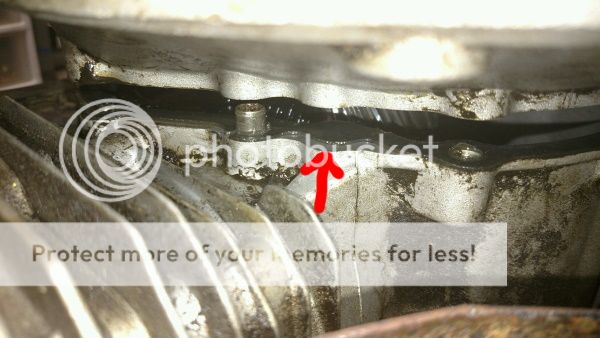

I think I found the source of the leak. Looks like the gasket may have gotten sucked in here? The red arrow shows the spot and that's about where the oil is coming from.

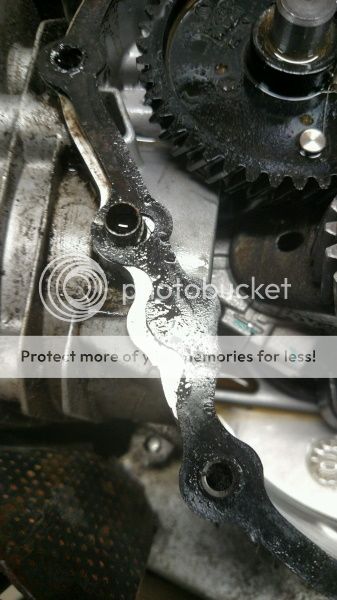

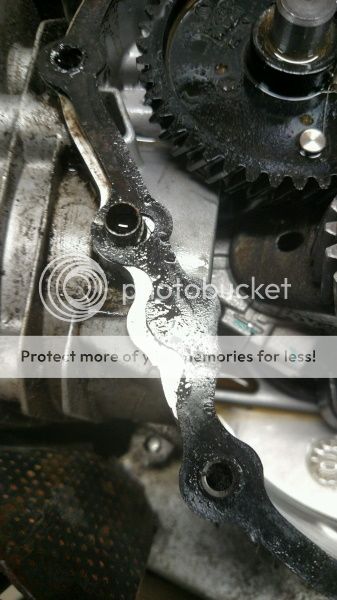

I also included a pic of the shaft, which you can see has some rust at the base. This must be where it's getting hung up. Maybe some emery cloth on that? I'm afraid to use sand paper with the the engine upside down and the seal removed. Sand getting into the case and what not.

Lastly, how much force should I be using to remove this cover? Should a rubber persuader be employed?

Amended: you can also see the long "crack" beneath but I think that is just a mark in the casting...or in my inexperience, I can't really tell yet.

I also included a pic of the shaft, which you can see has some rust at the base. This must be where it's getting hung up. Maybe some emery cloth on that? I'm afraid to use sand paper with the the engine upside down and the seal removed. Sand getting into the case and what not.

Lastly, how much force should I be using to remove this cover? Should a rubber persuader be employed?

Amended: you can also see the long "crack" beneath but I think that is just a mark in the casting...or in my inexperience, I can't really tell yet.

- lefty

- Forum Pro

- Posts: 1011

- Joined: Sun Jun 08, 2014 10:12 am

- Location: Massachusetts

Re: Toro Oil Sump

sand that rust off the crank down to shiny metal , then flush it out (spray carb cleaner or some such) (tap cover back down to keep grit out)

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: Toro Oil Sump

Worked like a charm. Thank you. Here's a better look at what I suspect may be the culprit for the oil leak. Am I on the right track?

Just curious of opinions on this: Do you think this was caused by the abrupt stop? Or maybe this condition was preexisting and the abrupt stop maybe jarred it enough to allow it to leak?

Thanks.

Just curious of opinions on this: Do you think this was caused by the abrupt stop? Or maybe this condition was preexisting and the abrupt stop maybe jarred it enough to allow it to leak?

Thanks.

- lefty

- Forum Pro

- Posts: 1011

- Joined: Sun Jun 08, 2014 10:12 am

- Location: Massachusetts

Re: Toro Oil Sump

I would say a combination of factors - Hot engine (thermal expansion) and tipping mower on its side to remove rags from blade, allows oil to plug up breather vent, then restart while still hot, there'd be enough vacuum (due to oil clogged breather that hadn't drained all oil back to crankcase yet) to suck in the gasket and cause the leak. It isn't unusual to see sump gaskets sucked in like that - more commonly found on engines that get worked hard, overheated (lack of maintenance of cooling system) or breather problems (As noted oil in breather box can cause a "seal" that it can generate excess vacuum that'd suck in a sump gasket) many manufacturers have replacement gaskets with an adhesive bead on the gasket to help prevent such events. Still want to check flywheel key (which if slightly sheared it may run but not at peak performance, and may overheat) any sudden stop of the engine should result in a check of flywheel key. (I've seen the shear just from mower hitting a heavy clump of cut grass)

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: Toro Oil Sump

Excellent. Thank you.

- lefty

- Forum Pro

- Posts: 1011

- Joined: Sun Jun 08, 2014 10:12 am

- Location: Massachusetts

Re: Toro Oil Sump

KE4AVB wrote:Agree with BGS.

Hopefully you disabled the valve train. If you didn't the springs will be applying pressure to the camshaft. Other that all I can think of would be the PTO end of the crankshaft must clean and burr free in order for the closure plate to come off. Also verify the crankshaft didn't get bent during the event as that make hard to get the closure plate off.

BTW for oil leaks of unknown origin I prefer to use UV dye to verify where the leak is. The XT is however just glued together so it could just failed. I have seen where when an engine have had into by another tech to leak because didn't follow the RTV instructions.

When re RTVing it make sure every contact area is cleaned of and a surface prep/accelerator is used. You be surprise how much is left behind as with using Q-tips they get quite dirty during the use of the surface prep. Once assembly the screws are to be just finger tight for 12-24 then torqued spec. [I know it say 30 minutes but the RTV isn't fully cured during this time frame] This gives time for the RTV to stick and cure properly. Personally I am using Permatex 24163 with both my RTVs and thread lock compounds. A good example of not fully is the Ultra Black that can still squeeze out 12 hrs later when doing valve covers here.

Should I be using the rtv in conjunction with the gasket?

Also, I've been able to find torque specs for everything that I've undone except for the engine mounting bolts that hold the engine to the deck. Do I just use common sense on those?

- lefty

- Forum Pro

- Posts: 1011

- Joined: Sun Jun 08, 2014 10:12 am

- Location: Massachusetts

17 posts

• Page 1 of 2 • 1, 2

Return to Technical Discussion Forum

Who is online

Users browsing this forum: Google [Bot] and 19 guests