Hmmm with some impacts out there now you can crack or split a flywheel at that taper mount and it can also make it nearly impossible to get back off later. I seen one last year that had two inch cracked across that taper which explained why the customer's flywheel was rubbing on the crankcase. He was doing his on overhaul and ran into this problem. I ask him what he torque it to and he said just used a 3/4 impact.

I sold him another engine that was already rebuilt. I paid him what costs for the parts he used basis on his receipts and have since sold those parts. As for the engine it went to the recycling center as he had screw it up otherwise too.

-

- Advertisement

B&S 31C707 0230 E1 030517ZE flywheel

28 posts

• Page 2 of 3 • 1, 2, 3

Re: B&S 31C707 0230 E1 030517ZE flywheel

The truest measure of society is the how it treats its elderly, its pets, and its prisoners.

-

KE4AVB - Forum Pro

- Posts: 6174

- Joined: Mon Nov 04, 2013 11:23 am

- Location: TorLand

Re: B&S 31C707 0230 E1 030517ZE flywheel

KE4AVB wrote:Hmmm with some impacts out there now you can crack or split a flywheel at that taper mount and it can also make it nearly impossible to get back off later. I seen one last year that had two inch cracked across that taper which explained why the customer's flywheel was rubbing on the crankcase. He was doing his on overhaul and ran into this problem. I ask him what he torque it to and he said just used a 3/4 impact.

I sold him another engine that was already rebuilt. I paid him what costs for the parts he used basis on his receipts and have since sold those parts. As for the engine it went to the recycling center as he had screw it up otherwise too.

How 'bout that.....didya notice that with some CARS out there you can go waaaay over 100mph!! Make it nearly impossible to extricate ya should you wreck!

So the lesson here is USE COMMON SENSE, no?

Just 'cause I recommend using an impact, it doesn't mean to blast it into oblivion. I've used an impact for years ( still do) with ZERO ISSUES!

You DID notice the OPs flywheel is cast iron, right?

http://ppeten.com/forums/viewtopic.php?f=4&t=836

I quote:

"Don't pay any attention to old Dummy."- okie

"pompous a**hole"- steinuit13

"I agree, Deere is a negative around here to say the least"-mek a nik

Nice, huh?

I quote:

"Don't pay any attention to old Dummy."- okie

"pompous a**hole"- steinuit13

"I agree, Deere is a negative around here to say the least"-mek a nik

Nice, huh?

-

Deere2me - Forum Pro

- Posts: 439

- Joined: Wed Jan 01, 2014 2:27 pm

- Location: Chesapeake, VA

Re: B&S 31C707 0230 E1 030517ZE flywheel

Doesn't matter - overtorque them, they can still split - have seen it myself - after somebody used a 1/2" impact with no common sense applied..Deere2me wrote:You DID notice the OPs flywheel is cast iron, right?

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: B&S 31C707 0230 E1 030517ZE flywheel

bgsengine wrote:Doesn't matter - overtorque them, they can still split - have seen it myself - after somebody used a 1/2" impact with no common sense applied..Deere2me wrote:You DID notice the OPs flywheel is cast iron, right?

Common sense being the key word!

Personally, Ive not seen a cast iron flywheel split...must be a Pennsyltucky thing!

http://ppeten.com/forums/viewtopic.php?f=4&t=836

I quote:

"Don't pay any attention to old Dummy."- okie

"pompous a**hole"- steinuit13

"I agree, Deere is a negative around here to say the least"-mek a nik

Nice, huh?

I quote:

"Don't pay any attention to old Dummy."- okie

"pompous a**hole"- steinuit13

"I agree, Deere is a negative around here to say the least"-mek a nik

Nice, huh?

-

Deere2me - Forum Pro

- Posts: 439

- Joined: Wed Jan 01, 2014 2:27 pm

- Location: Chesapeake, VA

Re: B&S 31C707 0230 E1 030517ZE flywheel

Deere2me wrote:Common sense being the key word!

Personally, Ive not seen a cast iron flywheel split...must be a Pennsyltucky thing!

Well I have seen one here on 12.5 Briggs and couldn't find an used one anywhere close. Customer retire it and the junk mower it was on. Cost more to fix both than a good used mower I had which he thought 350.00 with 90 day warranty was too much. He brought a 200.00 mower and spent another 300.00 fixing the deck and drive problems.

The truest measure of society is the how it treats its elderly, its pets, and its prisoners.

-

KE4AVB - Forum Pro

- Posts: 6174

- Joined: Mon Nov 04, 2013 11:23 am

- Location: TorLand

Re: B&S 31C707 0230 E1 030517ZE flywheel

Deere2me wrote:bgsengine wrote:Doesn't matter - overtorque them, they can still split - have seen it myself - after somebody used a 1/2" impact with no common sense applied..Deere2me wrote:You DID notice the OPs flywheel is cast iron, right?

Common sense being the key word!

Personally, Ive not seen a cast iron flywheel split...must be a Pennsyltucky thing!

I'm sure you will eventually

- after 30+ years in the business, working with them 6 - 7 days a week, Whether they were aluminum or cast Iron, Ive seen them split, cracked, broken, come loose, even cracked all the way around the hub so the flywheel would spin, but the crank would not turn... and even shattered to bits and blown out through the blower housing in shrapnel pieces (one of those was on a Wisconsin VH-4D.. glad no one was around that monster when the flywheel went... the other one also a cast iron flywheel on a Tecumseh 5 HP Snowblower - owner had "adjusted the governor" to make it blow snow further.. hehehe. )

Its entirely possible the one I saw split (A Briggs 15.5 HP OHV) from using an impact may have already been cracked from something else, allowing it to split right down the keyway.. no way to tell.. but that was the way it came in.

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: B&S 31C707 0230 E1 030517ZE flywheel

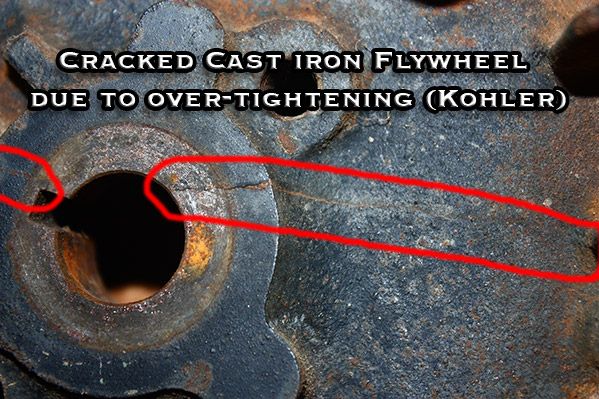

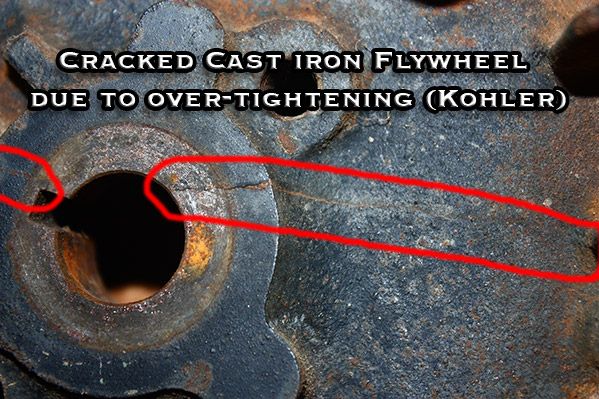

This flywheel came off of a Kohler that the customer brought to us because "it would not run anymore"...when customer was questioned about what lead up to the situation...he said......."I took the flywheel off to clean the magnets and get a rat nest out" after more questions.."Oh,..I just ran it up with my impact wrench".

It had sheared the key because the flywheel would no longer stay tight on the shaft due to the cracks spreading open.

They have torque specs for a reason......

It had sheared the key because the flywheel would no longer stay tight on the shaft due to the cracks spreading open.

They have torque specs for a reason......

-

GoatDriver - Posts: 27

- Joined: Thu Mar 06, 2014 9:59 pm

Re: B&S 31C707 0230 E1 030517ZE flywheel

I think I have common sense but I have not been so lucky lately  so I have a friend that has a bigger ft./lbs. torq wrench I can borrow. Suggestions on how to keep crank from spinning when torqing (not twerking

so I have a friend that has a bigger ft./lbs. torq wrench I can borrow. Suggestions on how to keep crank from spinning when torqing (not twerking  )???

)???

Some rope in the cylinder through the plug hole?

Not familiar with how much 110 ft./lbs. feels like. Is it possible a two person job, one holding the flywheel while the other torqs it down?? Neither person is Superman.

Thanks

Some rope in the cylinder through the plug hole?

Not familiar with how much 110 ft./lbs. feels like. Is it possible a two person job, one holding the flywheel while the other torqs it down?? Neither person is Superman.

Thanks

- jwales

- Guide

- Posts: 176

- Joined: Tue Nov 12, 2013 2:25 pm

- Location: Minnesota

Re: B&S 31C707 0230 E1 030517ZE flywheel

jwales wrote:I think I have common sense but I have not been so lucky latelyso I have a friend that has a bigger ft./lbs. torq wrench I can borrow. Suggestions on how to keep crank from spinning when torqing (not twerking

)???

Some rope in the cylinder through the plug hole?

Not familiar with how much 110 ft./lbs. feels like. Is it possible a two person job, one holding the flywheel while the other torqs it down?? Neither person is Superman.

Thanks

On a typical pushmower you can just block the blade with a chunk of wood, most manufacturers recommend using a strap wrench , one can be made from a piece of square tubing that a 1/2" drive breaker bar will fit in, cut a slot, and get some seat belt webbing from local auto junkyard or auto parts store and make a strap wrench from that to wrap around the flywheel - If you got the pecs for it, 150 Ft Lbs is not difficult at all , on average 110 Ft Lb is about as difficult, with a 1/2 inch drive torque wrench and a breaker bar being equal length, (about 18" to 24" handles) as, say, pushing a 50Lb bag of seed off a shelf - 110 Ft Lbs with 2 Ft of leverage means you need to apply 55 lbs of force at the end of the lever. with a 3 Ft lever, that is reduced to 36.66 Lbs of force applied.. with a 10 ft lever you could achieve that torque with an 11 pound weight force.

Easy calculation.

How poor are they who have not patience. What wound did ever heal, but by degrees? - Iago (Othello Act II, Scene 3)

- bgsengine

- Briggs MST

- Posts: 3361

- Joined: Sun Nov 03, 2013 10:07 pm

- Location: Northcentral P.A.

Re: B&S 31C707 0230 E1 030517ZE flywheel

Thanks for all the help. Got the flywheel key and a torq wrench to spec and (with previous work, head gasket,valve adjustment, carb cleaning) it runs great!

- jwales

- Guide

- Posts: 176

- Joined: Tue Nov 12, 2013 2:25 pm

- Location: Minnesota

28 posts

• Page 2 of 3 • 1, 2, 3

Return to Technical Discussion Forum

Who is online

Users browsing this forum: No registered users and 45 guests